Air Preheater

Air Preheater Manufacturer | Boiler Efficiency & Fuel Savings Solution

Thermokrupp Boilers manufactures high-efficiency Air Preheaters (APH) that increase combustion air temperature using waste flue gases, improving boiler efficiency by 5-10% and significantly reducing fuel consumption.

What is an Air Preheater (APH)?

An Air Preheater is an essential boiler component and a type of heat exchanger that increases the temperature of combustion air by recovering waste heat from hot flue gases. By preheating the incoming air, it ensures better combustion, reduces fuel consumption, and significantly improves overall boiler efficiency.

📍 Location in the Boiler System

The air preheater is typically installed between the economizer and the chimney, ensuring maximum heat recovery from flue gases before they exit the system.

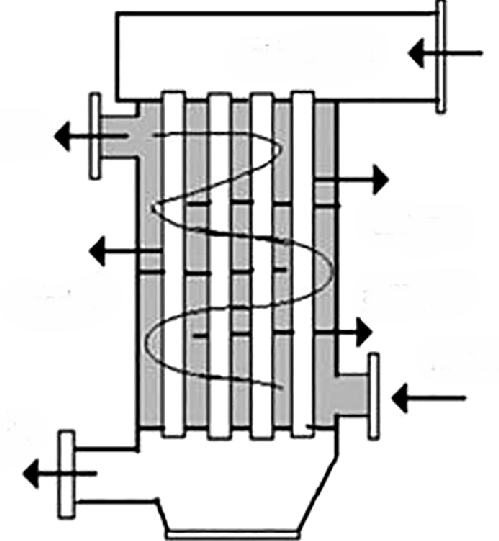

How Does an Air Preheater Work?

Hot Flue Gases Enter

Waste heat from boiler flue gases (200-400°C) enters the preheater tubes.

Air Circulation

Fresh atmospheric air flows externally over the hot tubes in counter-flow direction.

Heat Transfer

Baffles guide air across tubes multiple times for optimal heat absorption (50-150°C rise).

Improved Combustion

Preheated air enters furnace for complete, efficient combustion with less fuel.

Construction of Air Preheaters

Our tubular-type air preheaters feature robust construction:

- Multiple Tubes: Carry hot flue gases for heat transfer

- External Air Flow: Air flows over tubes for maximum heat exchange

- Baffle System: Guides air repeatedly over tubes

- Soot Hopper: Collects ash and particulates at bottom

- Corrosion-Resistant: Made from high-grade steel for durability

Advantages of Air Preheater

FAQs – Air Preheater Systems

1. How much efficiency improvement can I expect?

Properly sized air preheaters typically improve boiler efficiency by 5-10%, with fuel savings of 5-15% depending on boiler type and operating conditions.

2. Can it be retrofitted to existing boilers?

Yes, Thermokrupp designs custom air preheaters that can be retrofitted to most existing industrial boilers, with installation guidance and support.

3. What maintenance is required?

Regular cleaning of tubes, inspection of baffles, and emptying of soot hopper. Annual professional inspection recommended for optimal performance.

Boost Your Boiler Efficiency Today

Reduce fuel costs by 5-15% with a high-efficiency air preheater from India’s trusted boiler components manufacturer.