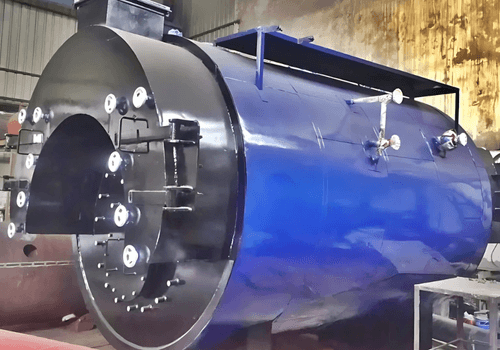

Boiler Efficiency Improvements

Boiler Efficiency Improvement Services | Maximize Performance, Slash Costs

As a top industrial steam boiler services provider, Thermokrupp Engineerings delivers expert boiler efficiency improvement services with over 90% accuracy. Our skilled, experienced team helps you recapture the 20-30% of your heating budget lost up the chimney.

The High Cost of Boiler Inefficiency

Your boiler likely accounts for the bulk of your heating fuel bill. Most boiler systems operate at just 70% to 80% efficiency, with best-case scenarios reaching only 85%.

This means 20% to 30% of your heating budget is wasted – going up the chimney with no benefit to your operation.

Our Precision Improvement Approach

Thermokrupp Engineerings provides a dual-path strategy to reclaim those losses and maximize your system’s lifespan and performance.

Ongoing O&M

Low/no-cost operational tweaks

Capital Upgrades

One-time investments for major gains

Tested Solutions for Maximum Boiler Efficiency

We implement proven, high-impact strategies to optimize combustion, recover waste heat, and improve system design. These are some of the key one-time investments we specialize in[citation:5][citation:8]:

🔥 Optimize Combustion & Reduce Excess Air

Precise management of the air-to-fuel ratio ensures complete combustion and minimizes heat loss up the stack. We tune burners and control systems for peak performance[citation:5].

💧 Install Condensate & Blowdown Heat Recovery

Capture and reuse the valuable heat from condensed steam and boiler blowdown water. This reduces the energy needed to heat incoming feedwater[citation:5][citation:8].

♨️ Implement Exhaust Heat Recovery (Economizers)

Economizers use waste heat from flue gases to preheat boiler feedwater. This is one of the most effective upgrades for fuel-fired systems[citation:5].

🛠️ Advanced Maintenance: Turbulators, Soot Blowers & Insulation

Enhance heat transfer, keep heat exchange surfaces clean, and minimize losses with strategic upgrades like turbulators, automated soot blowers, and optimized boiler insulation[citation:5].

Why Partner with Thermokrupp Engineerings?

>90% Accuracy

Our diagnostic and improvement services are delivered with exceptional precision.

Skilled, Experienced Team

Deep practical knowledge across all boiler types and industrial applications.

Holistic Analysis

We evaluate your entire system—from combustion and heat recovery to water treatment and controls[citation:5].

Clear ROI Focus

We prioritize solutions with measurable payback, ensuring your investment directly cuts fuel costs.

Stop Burning Money. Start Optimizing Your Boiler.

Get a professional efficiency audit and a customized plan to reduce your fuel consumption and operating costs.