Steam Distribution System

Steam Distribution System Design & Optimization | Reduce Energy Loss by 10%

Thermokrupp Boilers provides expert steam distribution system analysis, insulation, and optimization services to maximize efficiency, reduce fuel costs, and improve industrial process reliability.

The Hidden Cost of Poor Steam Distribution

Most industrial steam distribution systems suffer from significant parasitic heat losses due to inadequate insulation on straight pipes, valves, flanges, and joints. While this uninsulated piping might provide unintended “free” heating, it is completely uncontrolled and represents a major waste of energy and money.

This lack of insulation directly decreases system effectiveness, forcing your boiler to work harder and consume more fuel to maintain the required steam pressure and temperature at the point of use.

Our Solution: Comprehensive Thermographic Inspection

Identify Hidden Losses

Advanced infrared thermography quickly and accurately reveals heat loss hotspots across your entire steam network.

Critical Areas Scanned

We inspect boiler rooms, pre-blow areas, main distribution pipes, valves, flanges, joints, and areas around blow machines.

Detailed Analysis Report

Receive a comprehensive report with thermal images, loss calculations, and prioritized recommendations for improvement.

Maximize Efficiency with Professional Insulation

Simple, strategic insulation of major pipes and distribution valves represents a one-time investment with rapid returns. By reducing parasitic heat loss, you directly lower the load on your boiler.

Potential Fuel Reduction: Up to 10%

Proper insulation can reduce your boiler’s fuel consumption by up to 10%, delivering significant cost savings and a quick return on investment.

Our 4-Step Steam System Optimization Process

System Assessment

Comprehensive thermographic inspection and efficiency audit of your entire steam distribution network.

Loss Analysis

Identify and quantify heat losses from uninsulated pipes, valves, flanges, and other components.

Custom Solution Design

Recommend optimal insulation materials and methods tailored to your specific system and budget.

Implementation & Verification

Professional installation followed by post-optimization inspection to verify performance gains and savings.

Frequently Asked Questions – Steam Distribution Systems

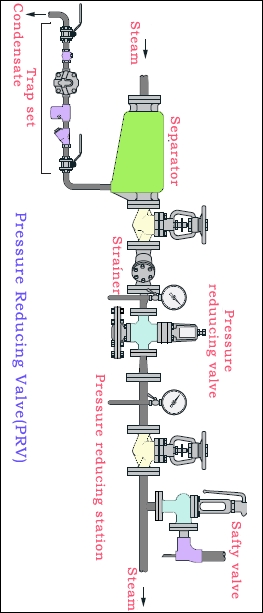

1. What is a steam distribution system and why is insulation critical?

+A steam distribution system is the network of pipes, valves, flanges, and fittings that delivers steam from the boiler to various points of use in an industrial plant. Insulation is critical because uninsulated components lose significant heat energy to the surroundings. This “parasitic loss” forces the boiler to consume extra fuel—often 5-10% more—to compensate, making proper insulation one of the most cost-effective efficiency investments.

2. How does thermographic inspection work?

+Thermographic inspection uses advanced infrared cameras to detect and visualize heat radiation. During a survey, our engineers scan your entire steam system. Areas with poor or missing insulation appear as bright “hot spots” on the thermal image, clearly showing where heat is escaping. This provides a rapid, non-invasive, and highly accurate assessment of energy losses from pipes, valves, flanges, and joints that are invisible to the naked eye.

3. What areas of the system typically need the most improvement?

+

The biggest heat losses often occur at complex components that are difficult to insulate. Key areas include:

• Valves and Actuators: Frequently left uninsulated for “ease of access.”

• Flanges and Joints: Gaps between pipe sections leak substantial heat.

• Steam Traps and Strainers: Often neglected in maintenance.

• Long, Uninsulated Pipe Runs: Especially in boiler rooms and pre-blow areas.

• Areas Around Blow Machines: Where high temperatures and maintenance access conflict.

4. Is this just about adding insulation, or are there other benefits?

+

While fuel savings of up to 10% are the primary benefit, a well-insulated system offers multiple advantages:

✓ Improved Safety: Reduces surface temperatures, minimizing burn risks.

✓ Consistent Steam Quality: Maintains correct pressure and temperature at point of use for better process control.

✓ Reduced Condensate: Less heat loss means less steam condensing in the pipes, improving efficiency.

✓ Extended Equipment Life: Reduces thermal cycling stress on pipes and components.

✓ Lower Carbon Footprint: Directly reduces greenhouse gas emissions from fuel combustion.

5. What is the typical return on investment (ROI) for system optimization?

+

ROI can be remarkably fast. For many facilities, the cost of professional insulation is recovered within 6 to 18 months through fuel savings alone. The exact payback period depends on:

• Current System Condition: The extent of uninsulated or poorly insulated areas.

• Fuel Costs: Higher energy prices accelerate ROI.

• Operating Hours: Systems that run continuously save more, faster.

• Scope of Work: Prioritizing the highest-loss areas first maximizes initial savings.

We provide a detailed savings estimate with our inspection report so you can make an informed decision.

Stop Heat Loss, Start Saving Money

Book a thermographic inspection or get a consultation for your steam distribution system. Reduce your energy bills by up to 10% with our expert optimization services.

Request an Inspection or Quote

Tell us about your steam system size, operating hours, and any specific concerns for a tailored proposal.

Contact Us Directly

Mon-Sat, 9:00 AM – 6:00 PM IST

Our Location

Thermokrupp Engineers

Kh No -12, Bisnoli, Tehsil – Dadri,

Gautam Budh Nagar – 203207,

Uttar Pradesh, India

Hours: Mon-Sat, 9:00 AM – 6:00 PM

Visits: By appointment only

Fast Assessment

Detailed proposal within 48 hours

Proven Savings

Up to 10% reduction in fuel costs

Quality Guarantee

On all materials and workmanship